How Are Bolts Made

Bolts come in many different shapes and sizes, depending on their final use. No matter what the bolt will be used for, the production process is mostly the same.

The four main stages are:

- Cold Forging

- Cutting the Thread

- Heat Treatment

- Surface Coating

How Are Bolts Made: Cold forging

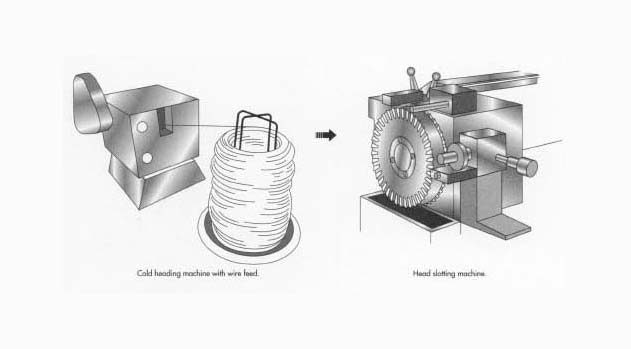

- Much the same way screws are made, cold forging starts with steel wire rods cut to length.

- At room temperature, the wire is then cold forged into the right shape by forcing it through a series of dies at high pressure. This complex tooling process can contain up to 200 different parts with tolerances of hundredths of a millimeter.

- Cold forging ensures bolts can be produced perfectly in large volumes, and at high speed production rate.

- At this point, some complex bolt designs that can’t be produced just through cold forging will require additional turning or drilling. Turning involves spinning the bolt at high speed, while steel is cut away to achieve the desired shape and design. Drilling can be used to make holes through the bolt. Depending on if the design calls for it, the bolts can have washers attached at this stage.

From steel wire, to cut rods. Bolts start life in a similar way to screws.

How Are Bolts Made: Cutting The Thread

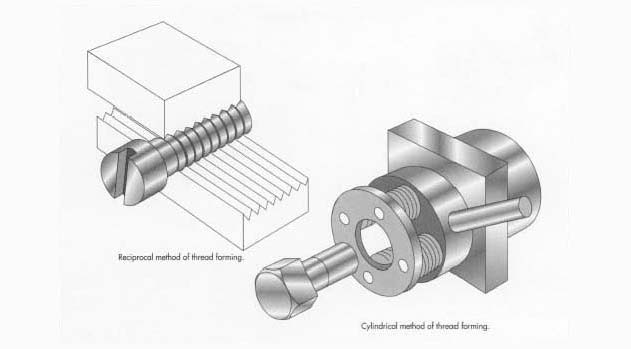

- Threading is usually applied before heat treatment, either by rolling or cutting when the steel is softer.

- Rolling works much like cold forging and involves running the bolt through a die to shape and mold the steel into threads.

- Cutting involves forming threads by cutting and removing steel.

Rolling or Cutting, moth methods are common foe the bolt to have it's threads cut.

How Are Bolts Made: Heat treatment

- Heat treatment is a standard process for all bolts, which involves exposing the bolt to extreme temperatures to harden the steel.

- Since heat treatment will change the properties of the steel to make it harder, it is easier and more cost-effective to apply threading beforehand.

Heat treating the bolts hardens them, giving them a long use life.

How Are Bolts Made: Surface Coating

- The type of coating is determined by the screws use. The main concern for screws is their corrosion resistance, so a zinc-plated coating is a common choice. This is a process where the screw is submerged in a liquid containing zinc, and an electric current is applied so that the zinc bonds to the screw forming a coating over the surface.

- While zinc coated screws are fine for indoor use, for outside you'll need something stronger. That's where we have other options such as galvanised zinc flake coating for superior corrosion resistance.

Once the surface treatment has been applied, standard bolts are typically ready to be packaged. However, more advanced designs may require some additional assembly, such as brackets, washers or nuts.

Other bolts will also require some form of patching, such as a locking patch - a thick nylon layer over the threads, that helps improve grip.

Once these steps are complete, the bolt is finished. Now all that remains is quality control to ensure consistency before the bolts are packaged and shipped.

Scrooz Cup Head Carriage Bolts all boxed and ready to send.

Need some new bolts? We have grab bags, trade boxes, and huge bulk boxes all from our factory right here: Bolts

Thanks for reading our latest blog entry

Best Regards,

The Scrooz Fasteners Team